Tags

Ward Charcoal Ovens State Historic Park

Willow creek, a year round stream located 1/4 mile to the north, was a major stopover for freighters on the Toano to Pioche route between 1870 and 1876. “Bullwhackers” (common term for freighters) would turn out their “Sleepers” (tired oxen) in this area and pick up rested ones to complete the journey.

In March of 1872, while searching for sleepers, John Henry and William Ballinger discovered silver ore in nearby Ward Gulch. By 1876 several claims were staked and the town of Ward grew to a population of 1,500 and had two roasting furnaces to process ore.

These 6 ovens were built in the mid 1870’s to make charcoal to fuel Wards roasting furnaces.

The overs were constructed by Italian masons and are larger and of finer construction than most ovens found in Nevada.

They measure 30 feet in height, 27 feet in diameter at the base and hold approximately 35 cords of wood. Each cord of wood produced 30 bushels of charcoal which was then hauled to the roasting furnaces at Ward.

As railroads penetrated the west, charcoal was replaced by coke made from coal and the charcoal making industry faded away. These ovens remain as a unique and silent reminder of Nevada’s mining history.

Related:

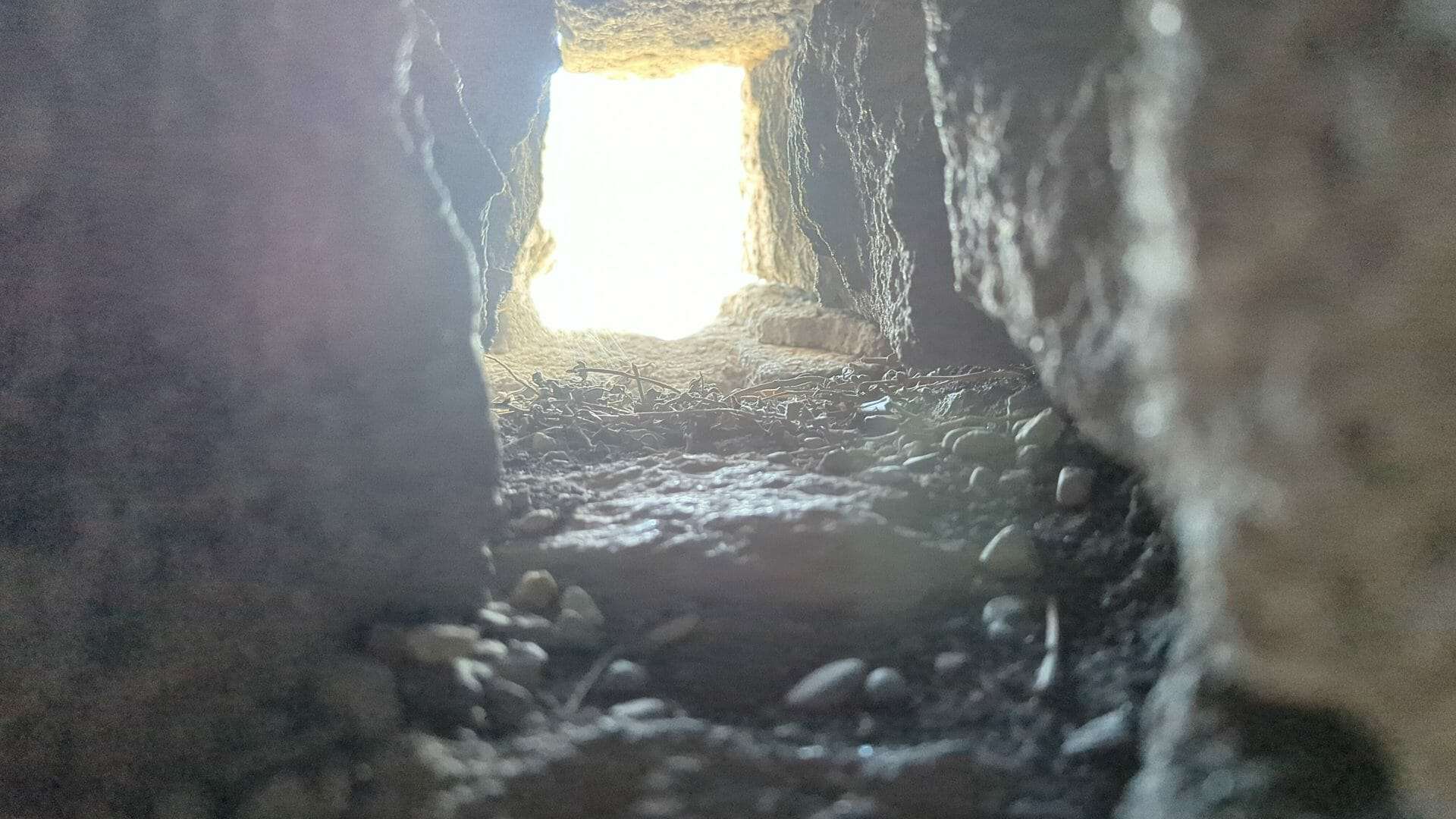

The charcoal making process took a total of 13 days and 35 cords of wood, from the time each oven was filled, burned, and then emptied. The wood was hauled by wagons or hand carts to the front of the oven, and the process of layering the wood inside the oven began. Once it was filled as high as possible using the front door, the wagons or hand carts were moved to a platform on the backside of the oven. The platform was level with the window above and the layering process was completed. Both openings were then closed off with iron doors, and the wood was set on fire. In September of 1879 the platform burnt to the ground.

Around the bottom of each oven are three rows of air vents. These were used to control the rate at which the wood would burn. During, the first 3 to 4 days the two lower rows were blocked off with rocks or bricks leaving the top row open. The smoke was watched to make sure the wood was burning at the desired rate. At first the smoke was white, almost steam-like in appearance. It would then change to yellow for 36 to 48 hours. The yellow smoke then changed to blue and was timed for 12 hours, at which time the top row of vents were closed and the second row of vents were opened. The process was then repeated, after which time the second row of vents were closed and the first row was opened. After this process was repeated one last time, all the vents were then sealed and the fire was allowed to extinguish itself. The oven remained sealed for approximately 3 days to insure the fire was completely out.

Once the kiln had cooled down, the doors were opened and the charcoal was removed by way of the lower opening. It was put into sacks holding one bushel and hauled either to holding area or to the furnaces at Ward.

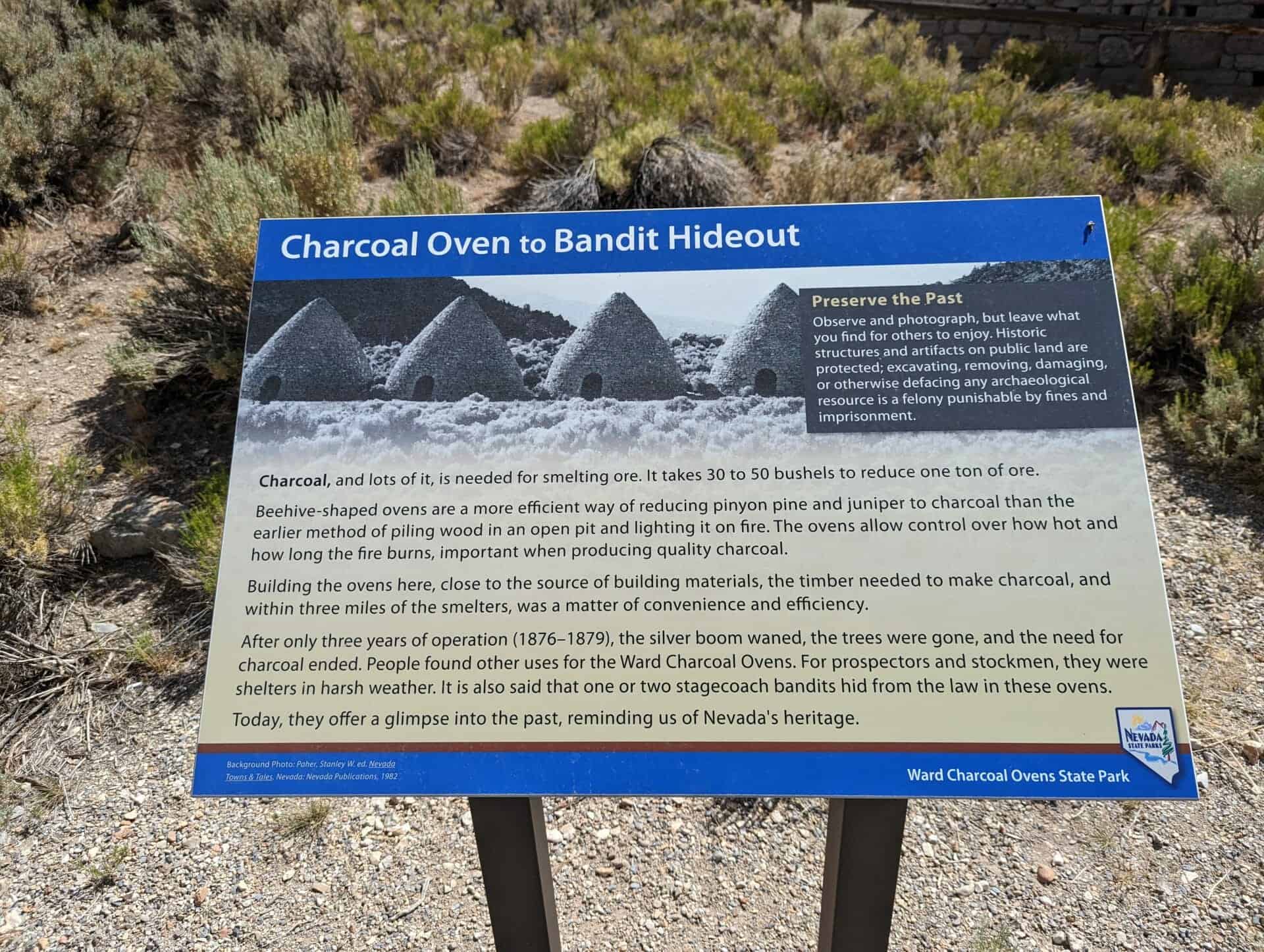

Charcoal, and lots of it, is needed for smelting ore. It takes 30 to 50 bushels to reduce one ton of ore.

Beehive-shaped ovens are a more efficient way of reducing pinyon pine and juniper to charcoal than the earlier method of piling wood in an open pit and lighting it on fire. The ovens allow control over how hot and how long the fire burns, important when producing quality charcoal.

Building the ovens here, close to the source of building materials, the timber needed to make charcoal, and within three miles of the smelters, was a matter of convenience and efficiency.

After only three years of operation (1876-1879), the silver boom waned, the trees were gone, and the need for charcoal ended. People found other uses for the Ward Charcoal Ovens. For prospectors and stockmen, they were shelters in harsh weather. It is also said that one or two stagecoach bandits hid from the law in these ovens.

Today, they offer a glimpse into the past, reminding us of Nevada’s heritage.

Charcoal burns slower and hotter than raw wood, a characteristic necessary for smelting ore. The charcoal was used in the smelters at nearby Ward. Timber was quickly stripped for miles around the ovens.

Filling one oven required trees from six acres of land.

1 oven = 6 acres of trees

6 ovens = 36 acres of trees

Each over held 35 cords of wood, which burned for 12 days, producing 50 bushels per cord.

50 bushels/cord x 35 cords = 1,750 bushels/oven

1,750 bushels/oven x 6 ovens = 10,500 bushels in 12 days!

Trees have not returned in all areas, but here in the park, some second-growth timber is emerging.